What is the meaning of TOPCon battery?

The full name of TOPCon is Tunnel Oxide Passivating Contacts, which translates to Tunneling Oxide Passivated Contacts, a N-type silicon wafer cell technology proposed in 2013.TOPCon cells, i.e. Tunneling Oxide Passivated Contacts solar cells, are designed to improve solar cell efficiency by solving the problem of selective passivation of the carriers in the cell.

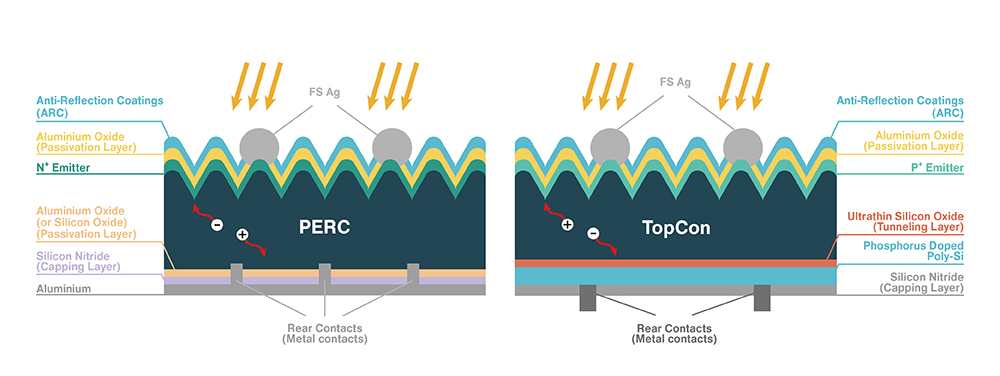

TOPCon cell front surface and conventional N-type solar cell structure is the same, the main difference in the back of the cell to prepare a layer of ultra-thin silicon oxide, and then a thin layer of doped silicon deposition, the two together form a passivated contact structure, effectively reducing the surface composite and metal contact composite.

Due to the good passivation effect of ultra-thin silicon oxide and heavily doped silicon film makes the surface energy bands of the silicon wafer to produce bending, thus forming a field passivation effect, the chances of electron tunneling increased dramatically, the contact resistance decreases, and ultimately improve the conversion efficiency.

Why TOPCon is replacing the PERC technology?

In 2023, the PV industry witnessed an important breakthrough with the addition of more than 400GW of new TOPCon production capacity. it is expected that TOPCon cell technology will overtake traditional PERC to become the new mainstream technology by 2024. In terms of production, it is expected that TOPCon production will reach about 100GW this year, accounting for 20%-30% of total PV cell production. As the most cost-effective N-type cell route, TOPCon cells are considered to be high-quality and scarce production capacity, and the situation of supply exceeding demand will persist throughout the year. With the continuous improvement of TOPCon battery efficiency, N-type TOPCon battery premium space is expected to further expand, which will have a positive impact on the business boom of the relevant companies.

N-type battery has not yet realized the key issue of large-scale production expansion is that its efficiency and P-type batteries have not opened a significant gap between the non-silicon cost of 30% -40% higher than the PERC battery. PERC battery efficiency has been close to the ceiling, the space to reduce the cost of space has been limited, but the efficiency of the TOPCon battery to improve still has great potential. According to PV Infolink's data, the current non-silicon cost of TOPCon cells is close to $0.3 per watt, compared with the cost of large-size PERC cells between $0.21-0.23 per watt, and there is still a gap. However, with subsequent continuous efforts, the production cost of TOPCon cells will gradually approach the level of PERC cells.

What are the advantages of TOPCon battery?

1. The advantage on passivation : the surface passivation performance mainly depends on the chemical passivation and field passivation, thermal growth of SiO2 has excellent chemical passivation ability. Heavy doping in polysilicon can induce the energy band of silicon to bend, resulting in the aggregation of majority carriers and depletion of minority carriers at the interface, reducing the composite and playing the role of field passivation.

2. The advantage on metal contact composite: metal contact composite becomes the bottleneck limiting the efficiency of conventional structure solar cell. Industrialization of metallization is usually screen printing after high temperature sintering, high temperature sintering process metal paste will "etch" poly-Si to form a "puncture" (Spiking), destroying the passivation of the contact structure, resulting in metal contact area of the J0c is higher in the metal contact area than in the passivated area. But p + poly and n + poly metal contact composite, even if the "puncture" will destroy the passivation contact structure of the case can make the metal composite is much lower than the conventional emitter / back field.

3. The advantage on metal contact resistivity: in addition to metal contact composite, metal-semiconductor contact resistivity (ρc) is also critical to the device performance of crystalline silicon solar cells, metal-semiconductor to form a good ohmic contact to help reduce the resistance loss and improve the fill factor.